Asphalt or post-tensioned concrete? Here’s what you need to consider.

Among the most common frustrations I hear from court and facility owners who have asphalt courts are cracking and unsafe surfaces. Owners looking for an improvement in court-surface life cycles often look to post-tensioned concrete surfaces as an alternative to the maintenance merry-go-round that asphalt courts can sometimes present.

Asphalt tennis courts have sustained popularity over the past decades due to their ease of construction and readily available materials associated with asphalt’s largest application – roadways and parking lots. Hot mix asphalt, be definition, is a flexible pavement which means that with time cracking of the pavement is inevitable and is part of the management of that type of pavement. While effective management of cracking is feasible and accepted for roadway and parking lot applications, these maintenance issues pose a significantly greater risk to the safety of tennis players, resulting in diminished performance and escalating maintenance costs.

Poor drainage and unstable subgrade soils also cause poor surface conditions on asphalt courts. A well-designed court or facility will include drainage to carry water away from the sub-base and provide stability for the court surface.

The American Sports Builder’s Association (ASBA) recommends sawing joints in asphalt courts. This helps relieve tension in the court surface and encourages cracking to occur on the sawed joints, which are outside the area of play. Sawed joints are a preventative measure, but new cracks can still form within the play surface, which needs to be taken into consideration when resurfacing courts.

Specialty Asphalt Mixes

While the primary application for asphalt pavements are roads and parking lots, be aware that the asphalt “mix” for these applications are not of the same quality needed for tennis courts and other playing surfaces.

Designers and builders have attempted to make adjustments to the typical parking lot asphalt mixes to make them more suitable for tennis court applications, with some success. There are recommended mix design properties provided through ASBA that should be used for construction of an asphalt court. Be aware that these specialty mixes cost more, and the relatively small quantities required result in challenges to both asphalt producers and installers.

This combination of the increased cost of specialty asphalt mixes and challenges of controlling asphalt quality have helped make concrete courts a more feasible option.

Advantages with PT Concrete

Post-tensioned concrete is a rigid, reinforced concrete pavement. Its design eliminates the jointing and cracking that plague asphalt courts. The lifespan of PT concrete can be almost double that of an asphalt court, as well.

Post-tensioned concrete can span unstable soils where asphalt would fail. Regions of the country with expansive soils have been using post-tensioned concrete for decades, with great success in residential and commercial applications.

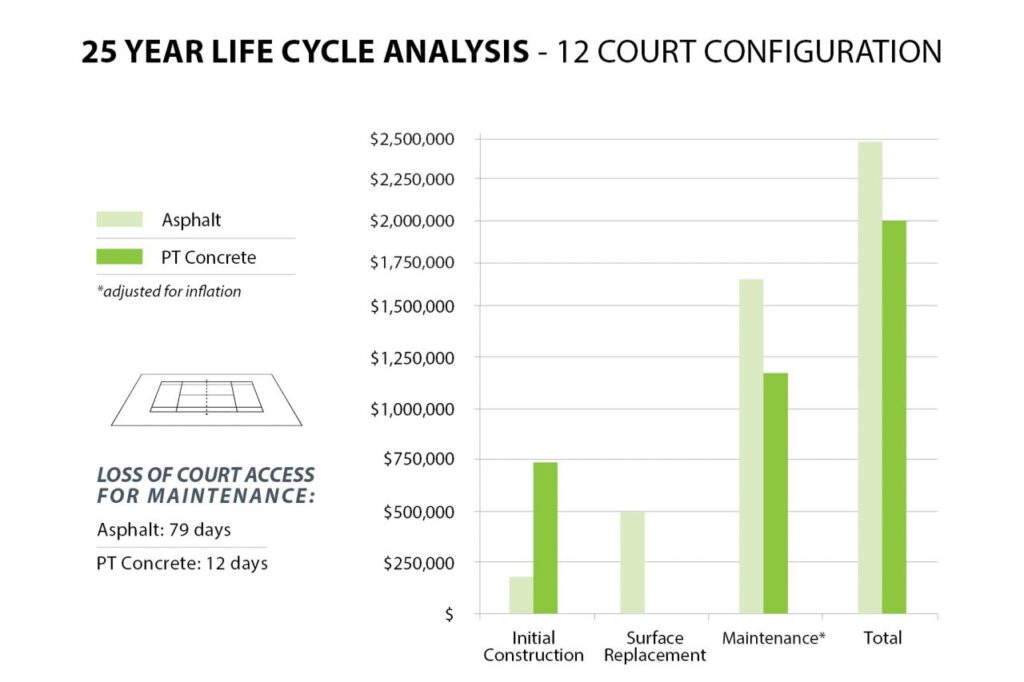

While post-tensioned concrete courts have an initial cost that is around 20 percent to 30 percent higher than that of asphalt courts, over the course of 25 years, you can anticipate that the inverse would be true. That is, after 25 years, the total cost of installing and maintaining post-tensioned concrete courts would be 20 percent to 30 percent less than for asphalt courts.

Additionally, you should expect to lose access to asphalt courts for up to 79 days over that time to make necessary repairs, compared with just 12 days for post tensioned concrete courts.

Let’s break this down a bit. All hard surface courts – whether they have an asphalt or post-tensioned concrete base – need to be resurfaced about every five years. This process typically takes two to three days, depending on the number of courts and weather conditions. In the case of asphalt courts, however, by the time a court is due to be resurfaced for the first time, it likely has developed initial cracking. These cracks need to be repaired before resurfacing can occur. That adds another two to four days to the process.

Repairing asphalt cracks is charged by the lineal foot. It’s common to see 100 to 200 feet of cracks per court – so if you have eight, 12, or more courts, the costs can really add up.

Another major repair of the asphalt gets underway around year 10 or 11. By this time, significant cracking is expected and will need to be addressed. And by the time 15 years have elapsed, most tennis facility owners are considering a total replacement of the asphalt surface. Replacing the courts will cause a loss of access of around 3 months.

The replacement of courts is, of course, an expensive proposition in and of itself. But the loss of court availability represents a lost opportunity to generate revenue.

Life Expectancy of PT Concrete Courts

A post-tensioned concrete court, in contrast, has a life expectancy of at least 25 years. Although there are many cases where courts have lasted for 30 or more years with the only maintenance required being resurfacing.

Installation of this type of court does require a unique concrete contractor. While not every contractor has this expertise, they are ubiquitous enough to find in most regions.

There are many benefits of post-tension concrete over asphalt for tennis court applications. Lower total costs over time, and less downtime due to maintenance, smooth, joint-free playing surfaces, and the long projected life cycle of the courts are some of the reasons you might consider post-tensioned concrete when it comes time to replace existing courts or when designing a new facility.

This article was originally published in the Tennis Industry publication, March 2019 and updated in August 2023.